As you start your car, the flywheel springs into action, storing mechanical energy generated by the engine's torque and powering the starter motor. During gear shifts, it connects to the clutch for a smooth change. By regulating power transfer between the engine and transmission, it maintains balanced engine speed and guarantees a smooth ride. Efficient energy storage and release enable your car to accelerate smoothly and respond swiftly to your commands. As you investigate the intricacies of your car's flywheel, you'll uncover how this critical component fine-tunes your driving experience and enhances performance.

Key Takeaways

- A flywheel stores mechanical energy generated by torque and powers the starter motor for engine startup.

- It connects to the clutch for seamless gear shifts and maintains balanced engine speed.

- The flywheel regulates power transfer between the engine and transmission, enhancing vehicle performance and driving experience.

- It reduces wear on components, extends clutch lifespan, and aids in smooth gear shifting.

- By maintaining stable engine rotation, the flywheel prevents sudden speed fluctuations and ensures a continuous energy supply.

Functions of a Flywheel

As you investigate the inner workings of your car, you'll find that the flywheel plays an important role in several key functions that impact your driving experience.

One significant function is its role in storing mechanical energy generated by torque, which is then utilized to power the starter motor when you turn the key. This energy is necessary for starting the engine, and the flywheel's ability to store and release it efficiently ensures a smooth startup.

Furthermore, the flywheel connects to the clutch, facilitating seamless gear shifts and maintaining a balanced engine speed. This balance is crucial for best vehicle performance, as it helps regulate the power transfer between the engine and transmission.

How Flywheels Store Energy

You're probably wondering how the flywheel manages to store the mechanical energy generated by torque, and the answer lies in its ability to rotate at incredibly high speeds.

When the engine produces torque, energy is transferred to the flywheel, which converts it into kinetic (movement) energy. As the flywheel spins, it stores this energy, allowing it to release it when needed. This process enables the engine to maintain a stable rotation, even during periods of low energy output.

The flywheel's high-speed rotation allows it to absorb and store energy, which is then released to provide additional power when required. This continuous energy supply is critical in intermittent engine operations, making flywheels an indispensable component in Mechanical Kinetic Energy Recovery Systems.

Balancing Engine Speed

Your car's engine relies on the flywheel to balance its speed, guaranteeing a seamless driving experience by storing and releasing mechanical energy generated by torque. As a mechanical device, the flywheel plays a critical role in maintaining stable engine rotation during acceleration and deceleration.

By connecting components to the clutch, the flywheel controls the engine speed and prevents sudden fluctuations.

Here are some key ways the flywheel balances engine speed:

- Stores and releases mechanical energy generated by torque to maintain stable engine rotation

- Prevents sudden fluctuations in engine speed during acceleration and deceleration

- Ensures continuous energy supply in intermittent engine operations

- Helps control the mechanical system orientation for an ideal driving experience

- Plays a critical role in maintaining stable engine rotation during acceleration and deceleration

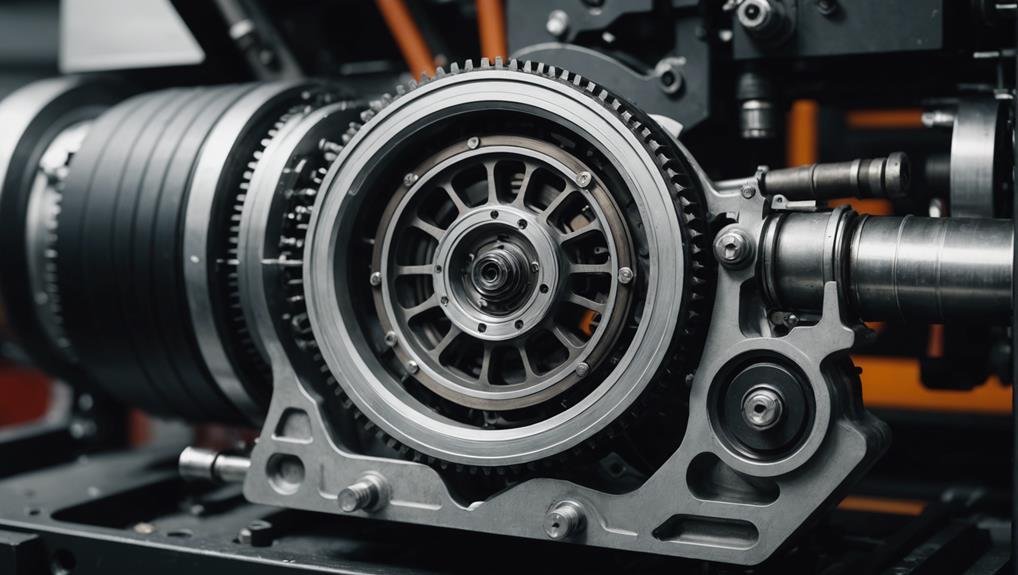

Types of Flywheel Designs

Flywheel designs vary, and understanding their differences is crucial in selecting the right type for your vehicle, with each catering to specific performance and durability requirements. You'll find that each design has its unique characteristics, advantages, and disadvantages.

For instance, a single mass flywheel directly connects the engine to the clutch, offering greater warp and thermal resistance, but may cause more noise and vibrations. On the other hand, a dual mass flywheel consists of two flywheels with springs to absorb vibrations, reducing noise and protecting the gearbox efficiently. The friction surface of a dual mass flywheel is designed to provide a smooth engagement and disengagement of the clutch.

Other types of flywheel designs include high-speed, low-speed, and lightweight flywheels, each with its own strengths and weaknesses. High-speed flywheels operate at extremely high speeds, while low-speed flywheels are larger and heavier, requiring regular maintenance. Lightweight flywheels, as their name suggests, reduce rotational mass to improve engine response.

Importance of Flywheel Maintenance

Once you've chosen the appropriate flywheel design for your vehicle, it's just as important to prioritize regular maintenance to avoid clutch problems and guarantee smooth engine operation. Proper flywheel maintenance is key to prevent costly repairs, extend the lifespan of the component, and ensure your vehicle runs efficiently.

Neglecting maintenance can lead to premature wear, overheating, and even catastrophic engine damage.

Here are some key reasons why regular flywheel maintenance is critical:

- Helps prevent clutch problems and ensures smooth engine operation

- Extends the lifespan of the flywheel and prevents costly repairs

- Allows for early identification of wear and damage, leading to timely repairs

- Prevents further damage to the engine or transmission

- Optimizes vehicle performance and safety by following manufacturer recommendations

Signs of a Failing Flywheel

As you drive, watch out for unusual noises, vibrations, or difficulty shifting gears, which can signal that your flywheel is failing. These signs of a failing flywheel can be subtle, but it's important to address them promptly to prevent further damage.

You might notice clutch chatter, which can be a sign of worn-out flywheel surfaces. Difficulty shifting gears or feeling vibrations while driving are also common indicators of a failing flywheel. Moreover, a burning smell during operation can be a sign of excessive heat generated by a malfunctioning flywheel.

Ignoring these signs can lead to poor engine performance, transmission damage, and even safety concerns. By being proactive and addressing these signs of a failing flywheel, you can prevent costly repairs and ensure your vehicle's safety.

Regular inspections and maintenance can help detect and address flywheel issues before they escalate. So, stay vigilant and take action if you notice any of these signs – your vehicle will thank you.

Replacing a Dual Mass Flywheel

When it's time to replace your dual mass flywheel, you'll need to prepare for a more involved process than a standard flywheel swap, requiring meticulous attention to detail to guarantee a smooth reinstallation. This is because dual mass flywheels serve a unique purpose, utilizing springs to absorb vibrations and protect the gearbox from damage.

To make sure a successful replacement, you'll need to inspect the flywheel needs, including the springs, friction surface, and bellhousing for damage.

Here are some key considerations to keep in mind when replacing a dual mass flywheel:

- The flywheel's springs must be checked for signs of wear or damage, as they play an important role in reducing vibrations.

- The friction surface should be examined for excessive wear or scoring, which can impact the flywheel's performance.

- The bellhousing must be inspected for damage or corrosion, as it provides a critical mounting point for the flywheel.

- The dual mass flywheel's unique design requires careful handling to avoid damaging the springs or other components.

- Proper alignment and installation are vital to make sure the flywheel functions as intended, serving its purpose of smoothing engine operation and providing a more comfortable driving experience.

Flywheel and Clutch Relationship

Your car's transmission and clutch rely on the flywheel to facilitate a seamless power transfer between the engine and gearbox. This is possible because the flywheel is designed to store rotational energy, which helps maintain momentum during gear changes.

When you shift gears, the clutch disconnects the engine from the gearbox, and the flywheel's stored energy ensures a smooth transfer of power. This synergy between the clutch and flywheel prevents engine stalling during gear changes, allowing you to shift gears smoothly.

As you drive, the flywheel and clutch work in tandem, with the flywheel aiding in balancing the engine's rotational forces. Over time, however, both components undergo wear and tear, making it advisable to replace them together.

By addressing signs of wear in both the flywheel and clutch, you can guarantee improved vehicle performance, a smoother driving experience, and a longer lifespan for these critical components.

Frequently Asked Questions

What Happens When Flywheel Fails?

"When your flywheel fails, you'll likely experience clutch slipping, difficulty shifting gears, and strange vibrations, noises, and smells – if you don't address it promptly, it'll lead to costly repairs and transmission damage."

What Are the 3 Main Purposes of a Flywheel?

You're wondering what the 3 main purposes of a flywheel are, right? Well, it stores rotational energy, provides continuous energy during intermittent operations, and releases stored energy to control mechanical system orientation – that's what!

Can You Drive a Car With a Broken Flywheel?

You shouldn't drive a car with a broken flywheel, as it can cause severe engine and transmission damage, leading to costly repairs and safety hazards.

How to Tell if a Flywheel Needs Replacing?

You'll know your flywheel needs replacing if you notice clutch chatter, difficulty shifting gears, unusual noises, vibrations, or a burning smell while driving, indicating it's time for a replacement to guarantee your vehicle's safety.

Conclusion

As you now understand the significance of a flywheel in a car, keep in mind that it plays a vital role in smoothing out engine speed, storing energy, and working in tandem with the clutch. Regular maintenance is essential to preventing premature wear and tear, and recognizing signs of failure can save you from costly repairs.

By grasping the complexities of flywheel design and function, you'll be better equipped to diagnose and address any issues that may arise, ensuring a smoother ride and prolonging the life of your vehicle.