When you shift gears, your car's gearbox translates engine power into torque and speed, propelling your vehicle forward. Gears transmit power by changing speed and torque, and gear ratios determine output speed and torque. The type of gearbox, such as manual, CVT, or planetary, impacts performance. Understanding gear ratios, mechanical power, and torque is essential for optimizing power transmission. Multiple gear stages and transmission ratios work together to modify torque output, and lubrication reduces friction and wear. By grasping these concepts, you'll uncover the intricate dance of gears and components that enables your car to move, and exploring further will reveal the intricacies of gearbox technology.

Key Takeaways

- Gearboxes translate power by changing speed and torque through gear ratios, which impact performance and efficiency.

- The number of gears and gear ratio determine output speed and torque, with higher ratios resulting in lower output speeds.

- Different gearbox types, such as manual, CVT, and planetary, offer unique capabilities and characteristics suited to specific applications.

- Gear ratios modify torque output, and understanding power, torque, and gear ratios is crucial for optimizing performance and power transmission.

- Proper gear selection and ratio adjustment can optimize power output, boost performance, and balance torque and speed for efficient transmission.

Understanding Gearbox Fundamentals

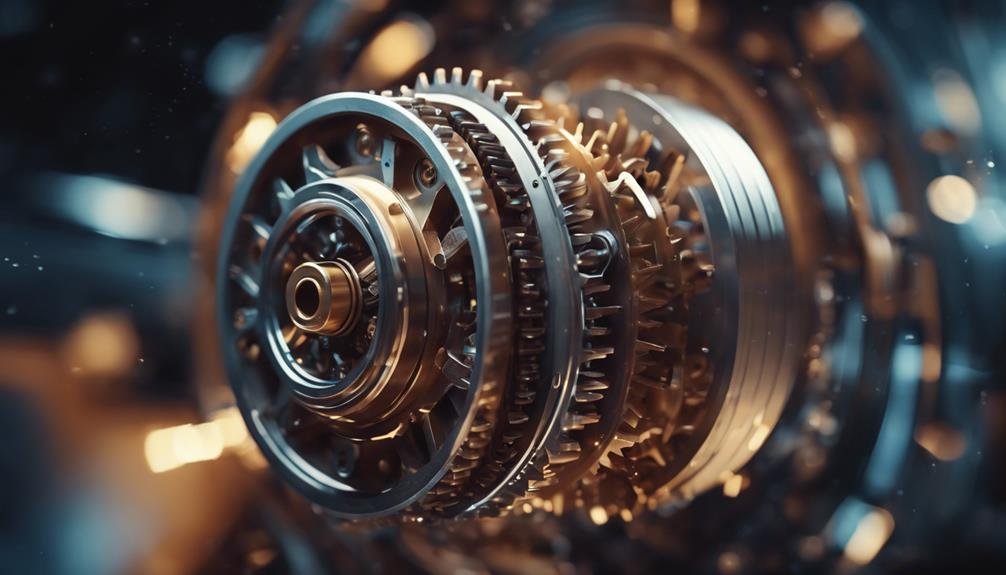

When you investigate the world of gearboxes, it's essential to understand the fundamental concept that these mechanical wonders transmit power from a motor to a driven system by cleverly changing speed and torque.

This process involves using gears with different sizes and numbers of teeth to achieve the desired speed and torque output. The gear ratio, which is the ratio of the number of teeth on two adjacent gears, plays an important role in determining the output. Gearboxes can increase torque while decreasing speed, or vice versa, depending on the gear ratio selected.

The number of gears in a gearbox also affects its performance, with more gears providing a wider range of speed and torque options. As you explore further into the world of gearboxes, you'll realize that different types, such as Planetary, Worm, and Bevel, offer unique speed reduction capabilities for specific applications.

Gear Ratios and Speed Conversion

As you delve into the intricacies of gearboxes, you'll find that gear ratios play a vital role in converting input speed to desired output speed, making them an integral aspect of speed conversion.

Fundamentally, gear ratios determine the relationship between input and output speeds in a gearbox. A higher gear ratio means the output speed is lower than the input speed, which is pivotal for efficient power transmission.

In a gearbox, different gear ratios are used to convert rotational speed to desired values. These ratios are calculated based on the number of teeth on gears in a gearbox. For instance, if one gear has 20 teeth and another has 40 teeth, the gear ratio would be 2:1, resulting in a slower output speed.

The transmission ratio in a gearbox affects the speed conversion process between input and output shafts. By adjusting the gear ratios, the gearbox can optimize power transmission, allowing for smooth acceleration, efficient fuel consumption, and improved overall performance.

Types of Gearbox Transmissions

You'll encounter a range of gearbox transmissions, each designed to serve specific purposes, from manual and automatic to CVT, planetary, and right-angle worm gearboxes. Each type of gearbox transmission has its unique characteristics, advantages, and applications.

Here are three key gearbox types you should know:

- Manual Transmissions: Allow for gear selection control, giving drivers more control over gear ratios for best performance and efficiency.

- CVTs (Continuously Variable Transmissions): Offer seamless gear ratio adjustments for best performance and efficiency, making them ideal for applications where speed and torque vary frequently.

- Planetary Gearboxes: Provide compact design with high torque capacity, making them suitable for applications where space is limited.

Understanding the characteristics and applications of different gearbox types is crucial for selecting the most suitable transmission for specific mechanical systems. By grasping the strengths and weaknesses of each gearbox type, you'll be better equipped to design, build, or maintain efficient mechanical systems that meet specific performance requirements.

Mechanical Power and Torque

To optimize gearbox performance, it's important to understand the fundamental concepts of mechanical power and torque, which directly impact the efficiency of mechanical systems. As you explore the world of gearboxes, you'll discover that mechanical power is the rate at which work is done, calculated as the product of force and velocity.

Torque, on the other hand, is the rotational force produced by an engine, important for generating mechanical power. Gearboxes play a significant role in translating mechanical power into desired torque outputs for efficient operation. Torque is necessary for overcoming resistance and driving mechanical systems, with gearboxes playing a key role in torque delivery.

When you adjust gear ratios, you're essentially modifying the torque output to match the required speed and force. By understanding the interplay between power, torque, and gear ratios, you'll be better equipped to optimize gearbox performance and ensure effective power transmission.

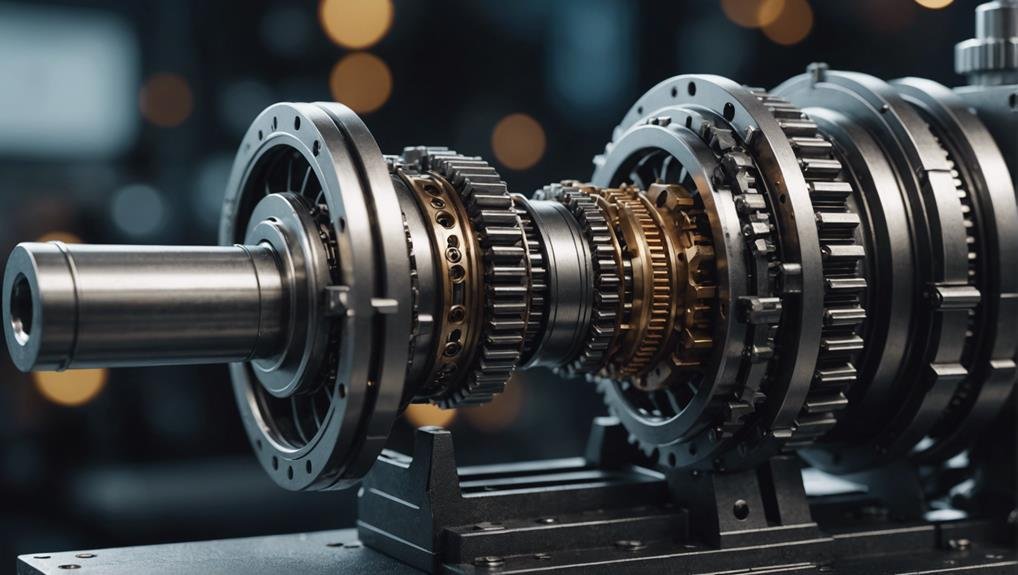

Gearbox Components and Lubrication

Inside a gearbox, a set of critical components – including gears, shafts, bearings, and seals – work together seamlessly to transmit power efficiently. As you investigate the inner workings of a gearbox, you'll uncover how each component plays a pivotal role in power transmission.

Here are three important components that make it all possible:

- Bearings: Supporting shafts and reducing friction, bearings improve power transmission efficiency.

- Seals: Preventing leakage of lubricants and contaminants, seals maintain a clean and functional internal environment.

- Gears and Shafts: Working in harmony, gears and shafts transmit power efficiently, ensuring smooth operation.

Lubrication is also necessary in gearboxes, reducing friction and wear between components. The type of lubricant used depends on the gearbox design and load requirements.

Gear Stages and Transmission Ratios

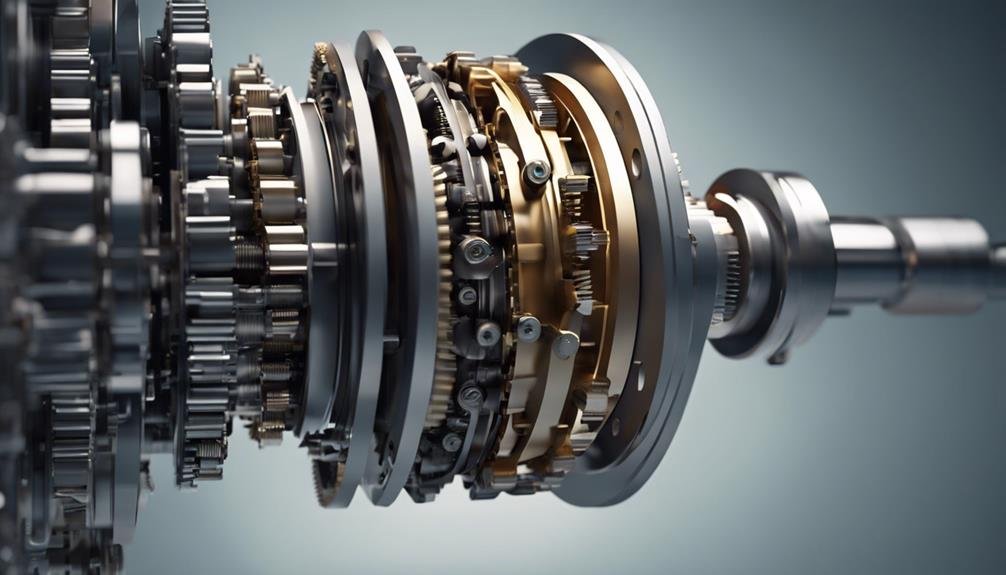

As you examine the inner workings of a gearbox, you'll find that the gearbox's ability to transmit power efficiently relies on its gear stages, which are specifically designed to change speed or torque through carefully calibrated transmission ratios.

These gear stages are essentially sets of gears that work together to achieve the desired output speed or torque. The transmission ratios, in turn, are determined by the number of teeth or pitch circle diameters of the gears involved.

By combining multiple gear stages, a gearbox can achieve the best transmission ratio for efficient mechanical power transmission. This is important, as the right transmission ratio ensures that the output speed and torque are precisely what's needed for a particular application.

As you explore further, you'll realize that understanding gear stages and transmission ratios is essential for optimizing power transfer in different applications, from heavy machinery to high-performance vehicles.

Optimizing Power Output and Performance

By adjusting the gear ratio, you can harness the full potential of your machinery, guaranteeing that power output is optimized for maximum performance. In a gearbox, the gear ratio plays a vital role in translating power by balancing speed and torque for efficient performance.

Proper gear selection is vital to boost performance, as it improves acceleration and overall efficiency.

Here are three key aspects to ponder when optimizing power output and performance:

- Gear ratio selection: The right gear ratio ensures that power output is maximized, taking into account the machinery's speed and torque requirements.

- Torque and speed balance: A well-adjusted gear ratio balances torque and speed, resulting in efficient power transmission and peak performance.

- Efficient power transmission: The gearbox's efficiency in transmitting power is directly influenced by the selected gear ratio, making it crucial to optimize gear selection for specific driving conditions.

Frequently Asked Questions

How Do Gears Transmit Power?

You'll find that gears transmit power by meshing teeth, creating a mechanical advantage that efficiently transfers rotational motion from one gear to another, adjusting speed and torque in the process.

How Is Power Multiplied Through a Gearbox?

As you explore gearboxes, you'll find that power multiplication occurs when you adjust gear ratios, increasing torque while decreasing speed or vice versa, resulting in optimized power output for specific applications.

How Does a Transmission Transfer Power?

You're wondering how a transmission transfers power? Well, it's quite simple: you see, a transmission adjusts gear ratios to regulate speed and torque output, allowing your vehicle to move efficiently, and it does this by controlling rotational speeds through different gear stages.

Does Power Change Through a Gearbox?

You're wondering if power changes through a gearbox? The answer is no, it doesn't! Power remains constant, and the gearbox only adjusts torque and speed to maintain that power output, ensuring efficient transmission.

Conclusion

Now that you've explored the world of gearboxes, you've gained a deeper understanding of how power is translated to achieve peak performance.

By grasping gear ratios, transmission types, and mechanical power, you can appreciate the intricate interplay of components working together.

As you progress, keep in mind that each gear stage and transmission ratio plays a vital role in maximizing power output, ultimately enhancing your vehicle's overall efficiency.