In your engine, a crucial component known as a lifter plays an essential role in facilitating smooth valve operation by acting as a shock absorber between the camshaft and pushrods, ensuring proper valve timing and engine efficiency. Lifters come in three types: hydraulic, mechanical, and solid, each serving a specific purpose, such as providing automatic valve clearance adjustment or precise control. By transferring motion from the camshaft to valves, lifters guarantee precise timing for valve opening and closing, ensuring efficient engine performance and facilitating airflow into cylinders. Now that you know what lifters do, you're ready to delve into their inner workings and maintenance needs in more depth.

Key Takeaways

- Engine lifters sit between the camshaft and pushrods, facilitating smooth valve operation and acting as shock absorbers in the valve train system.

- Hydraulic lifters use pressurized oil for automatic valve clearance adjustment, making them ideal for daily driving, while mechanical lifters require manual adjustments.

- Lifters transfer motion from the camshaft to valves, guaranteeing precise timing for valve opening and closing, and ensuring efficient engine performance.

- Lifters facilitate the flow of air and fuel into engine cylinders, making them critical for engine longevity and power output.

- Neglecting lifter maintenance can lead to costly repairs, so regular oil level and quality checks, valve clearance adjustments, and internal leak inspections are essential.

Lifter Function and Purpose

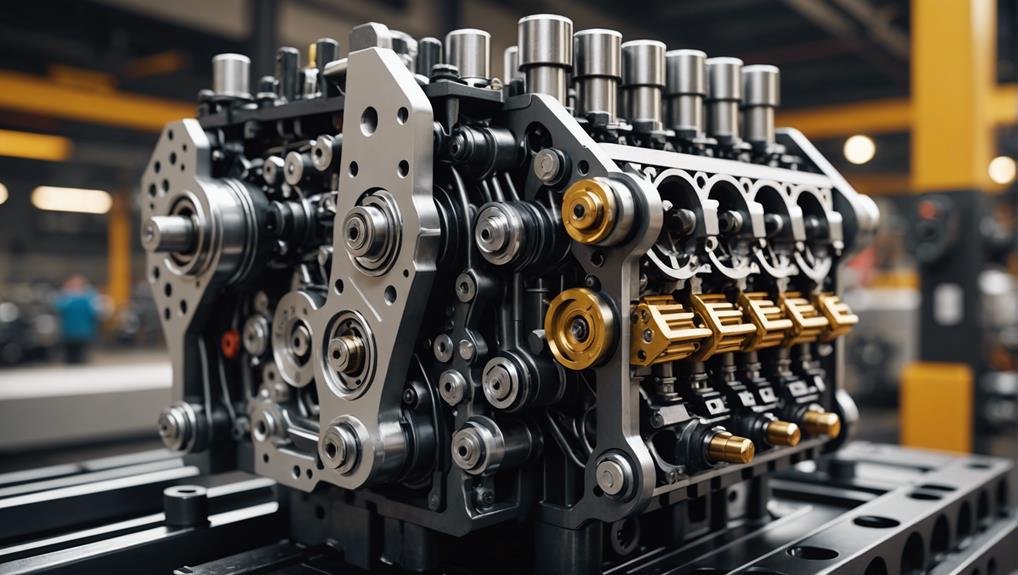

As you investigate the inner workings of your engine, you'll find that lifters play a key role in facilitating the smooth operation of your valves. Essentially, lifters sit between the camshaft and pushrods, transferring motion to open and close valves. This critical function allows for efficient engine performance, as lifters act as shock absorbers in the valve train system, reducing wear and preventing component separation.

By pushing pushrods, which in turn open rocker arms to operate valves, lifters ensure smooth valve operation. Proper lifter function is important for maintaining valve timing, engine efficiency, power output, and the overall performance of the engine. Without functioning lifters, issues like excess lash in the valve train system can arise, leading to engine malfunction.

It's important to understand that collapsed lifters indicate a problem, and addressing it promptly is crucial to prevent further damage. By grasping the importance of lifter function, you'll better appreciate the intricate mechanisms at play in your engine, allowing you to take better care of your vehicle.

Types of Engine Lifters

Regarding engine lifters, you'll find two primary types: hydraulic lifters and mechanical lifters, each with distinct designs and operational characteristics that cater to different engine needs and performance requirements. Hydraulic lifters use pressurized oil to adjust valve clearance automatically, reducing noise and maintenance requirements. They're favored in modern engines for their quieter operation and self-adjusting capabilities. Mechanical lifters, on the other hand, require manual clearance adjustments and are commonly found in racing applications for precise control.

Here's a comparison of the two types:

| Lifter Type | Design | Operation |

|---|---|---|

| Hydraulic Lifters | Self-adjusting | Automatic valve clearance adjustment |

| Mechanical Lifters | Manual adjustment | Requires manual clearance adjustments |

| Solid Lifters | Solid body | No hydraulic cushioning |

Hydraulic lifters are ideal for daily driving, as they provide smooth valve control and eliminate the need for frequent adjustments. Mechanical lifters, including solid lifters and roller lifters, are better suited for high-performance applications where precise control is vital. Understanding the differences between these lifter types is necessary for optimizing engine performance and reliability.

How Lifters Operate

You engage the lifter's operation when you start the engine, and it immediately begins transferring motion from the camshaft to the valves. This motion is important in the valve train system, as it guarantees precise timing for the opening and closing of intake and exhaust valves.

The lifter's design allows for smooth and efficient operation of the engine's valves, controlling the flow of air and fuel to achieve excellent engine performance. As the camshaft rotates, the lifter transfers motion to the valves, facilitating the flow of air and fuel into the engine's cylinders. This precise timing is crucial for efficient combustion, power output, and engine longevity.

The lifter's operation is critical in maintaining excellent engine performance, and its efficient design ensures that the valves open and close at the right time, every time. By transferring motion from the camshaft to the valves, the lifter plays an important role in the engine's valve train system, ultimately contributing to the engine's overall performance and longevity.

Lifter Maintenance and Repair

Properly maintaining your engine's lifters is essential to prevent issues like valve train noise, poor engine performance, and potential engine damage. Regular maintenance involves checking for proper oil levels and quality to guarantee smooth lifter operation. Neglecting lifter maintenance can lead to costly repairs down the line.

Here are some key aspects of lifter maintenance and repair to keep in mind:

- Oil levels and quality: Make sure the oil is at the recommended level and of good quality to prevent wear on lifter components.

- Valve clearance adjustment: Adjusting valve clearance is vital to prevent issues with engine performance and potential damage.

- Internal leak inspection: Inspect for internal leaks that can affect lifter operation and engine performance.

- Lifter component replacement: Replace worn-out lifter components to prevent further damage and ensure top engine performance.

Common Lifter Failure Symptoms

When your engine starts making unusual noises, such as ticking or tapping sounds, it may be a sign that your lifters are failing. These common symptoms can be indicative of a larger issue, and it's important to address them promptly to prevent engine damage.

| Symptom | Description |

|---|---|

| Ticking or Tapping Noises | Unusual engine sounds that may indicate faulty lifters |

| Reduced Performance | Decreased engine power, misfires, or rough idling |

| Low Oil Pressure | Insufficient lubrication, causing lifter failure |

If you notice any of these symptoms, it's vital to investigate further. Low oil pressure, engine overheating, or oil contamination can all contribute to lifter failure. Engine stalling or loss of power under acceleration could also be linked to faulty lifters. By recognizing these common symptoms, you can take proactive steps to prevent engine damage and make sure your vehicle runs smoothly. Remember, addressing lifter failure promptly is key to preventing further engine damage. Don't ignore these warning signs – take action to safeguard your engine's health.

Lifter Replacement and Upgrade

Swapping out faulty lifters with high-performance alternatives can greatly improve your engine's overall performance and longevity. When considering lifter replacement, it's crucial to match the lifter type with the camshaft type for best performance. Upgrading to performance lifters with tighter tolerances can enhance oil control and overall engine performance.

Here are some key considerations for lifter replacement and upgrade:

- Matching lifter type to camshaft type for best performance.

- Proper bleed-down of hydraulic lifters to prevent valve float or collapsing.

- Reducing friction with roller lifters, allowing for higher engine RPMs.

- Regular maintenance and inspection of lifters for smooth engine operation and longevity.

Frequently Asked Questions

What Does an Engine Lifter Do?

You're wondering what an engine lifter does? It guarantees precise valve operation by transferring motion from the camshaft, acting as a shock absorber to prevent wear, and maintaining valve clearance and timing for peak engine performance.

What Happens When Engine Lifters Fail?

When your engine lifters fail, you'll likely hear ticking or tapping sounds from the engine, and experience misfires, loss of power, and poor fuel efficiency, so it's essential you address the issue promptly to prevent further damage.

How Much Does It Cost to Replace an Engine Lifter?

You're looking at a cost of $300 to $1,000 to replace an engine lifter, plus labor costs of $300 to $500, depending on your car's make and model, with DIY kits available for $100 to $200.

Can You Run an Engine With a Bad Lifter?

You can technically run an engine with a bad lifter, but it's not recommended as it'll lead to valve train noise, reduced performance, and potential valve damage, ultimately causing more harm and expensive repairs down the line.

Conclusion

Now that you've learned about engine lifters, you know how essential they are to your engine's performance.

By understanding how lifters operate, you can identify symptoms of lifter failure and take prompt action.

Regular maintenance and timely replacement can prevent more costly repairs down the road.

With this knowledge, you're better equipped to keep your engine running smoothly and efficiently, ensuring a longer lifespan and peak performance.