You're about to delve into the world of carburetors, where different designs cater to specific engine needs. From single venturi carburetors suited for smaller engines to multiple venturi designs for high-performance engines, each type regulates fuel flow differently. Progressive barrel carburetors open additional barrels at higher speeds, while primary and secondary barrels optimize fuel efficiency. Float-type carburetors guarantee consistent fuel supply, while pressure-type carburetors deliver fuel under pressure. Different materials are used to guarantee smooth fuel flow and resistance to corrosion. As you continue, you'll uncover how to select the right carburetor for your engine's specific needs and unlock peak performance.

Key Takeaways

- Fixed Venturi carburetors regulate fuel flow based on airflow velocity, while Variable Venturi controls fuel flow mechanically.

- Single Venturi carburetors are suited for smaller engines, regulating fuel flow based on airflow velocity.

- Multiple Venturi carburetors, such as two-barrel and four-barrel designs, improve power and efficiency in high-performance engines.

- Float-Type carburetors use a float mechanism to adjust fuel flow based on fuel levels, ensuring a consistent fuel supply to the engine.

- Pressure-Type carburetors deliver fuel under pressure to engine cylinders, ideal for high-performance engines that require consistent fuel flow.

Understanding Carburetor Basics

As you delve into the world of carburetors, it's important to understand the fundamental principles governing their operation. At its core, a carburetor is a mechanical device that mixes air and fuel for internal combustion engines.

The process begins when you press the throttle, creating a vital-pressure area in the venturi, which draws fuel into the airflow. The air filter guarantees clean air enters the intake manifold, where the fuel-air mixture is created. The fuel pump supplies the necessary pressure to maintain this mixture.

As engine RPM increases, the carburetor adjusts the fuel flow to maintain ideal fuel efficiency. However, if the engine is running too rich or too lean, it can lead to issues like carburetor ice, which can cause engine failure.

Understanding these basics is crucial for maintaining and tuning older vehicles with carburetor systems. By grasping these fundamental principles, you'll be better equipped to diagnose and fix common issues, ensuring your vehicle runs smoothly and efficiently.

Types of Carburetor Designs

You'll encounter different types of carburetor designs, each catering to specific engine requirements and performance needs. As you delve into the world of carburetors, you'll come across different designs that cater to distinct engine requirements and performance needs.

Here's a breakdown of some common carburetor designs:

| Carburetor Design | Description |

|---|---|

| Fixed Venturi | Regulates fuel flow based on airflow velocity |

| Variable Venturi | Controls fuel flow mechanically |

| Downdraft | Common in vehicles, with intake manifold on top |

| Side-Draft | Common in vehicles, with intake manifold on side |

| Progressive Barrel | Opens up additional barrels at higher speeds |

These designs impact how fuel is delivered to the engine. In a carburetor, a throttle valve regulates airflow, while a float chamber maintains the ideal fuel level. The intake system, which includes the carburetor, ensures a precise air-fuel mixture reaches the engine. With two or more barrels, carburetors can provide increased power and efficiency. Understanding these designs is essential for optimizing engine performance and fuel efficiency.

Single Venturi Carburetors

With their simplicity and compact design, single venturi carburetors are well-suited for smaller engines, regulating fuel flow based on airflow velocity.

As you investigate how this type of carburetor works, you'll notice it has a single narrow section, called a venturi, where airflow converges, creating a region of low air pressure. This venturi design enables the carburetor to mix fuel with air effectively, producing a consistent fuel/air mixture.

When you accelerate, the flow of air increases, which, in turn, increases the flow of fuel, ensuring a consistent delivery of fuel to the engine.

Single barrel carburetors are commonly used in smaller vehicles like motorcycles, lawn mowers, and small boats, where power requirements are lower.

The carburetor works by using the venturi effect to create a region of low air pressure, which pulls fuel into the air stream, creating a precise fuel/air mixture.

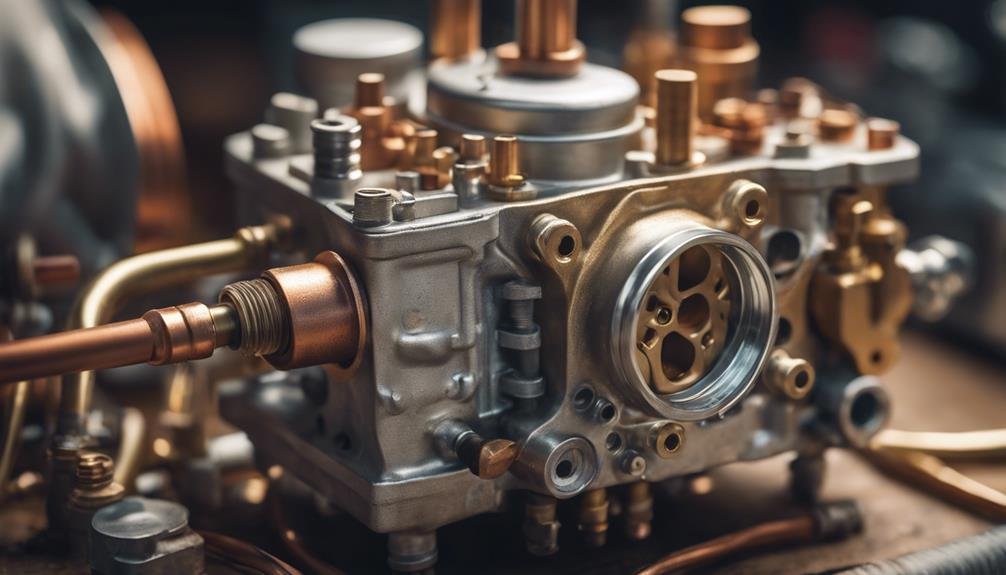

Multiple Venturi Carburetors

Multiple venturi carburetors, which include two-barrel and four-barrel designs, raise fuel delivery to the next level by incorporating extra venturis to improve power and efficiency.

You'll find that these carburetors, especially two-barrel designs, provide more airflow, allowing for improved fuel distribution and combustion. This results in a significant increase in power and efficiency, making them ideal for high-performance engines.

Four-barrel carburetors, on the other hand, take it a step further by incorporating both primary and secondary barrels. The secondary barrels open up at higher speeds, providing an additional power surge.

In some multiple venturi carburetors, you'll find progressive barrels that optimize fuel efficiency by adjusting airflow and fuel mix based on engine load and speed. This technology ensures that your engine runs smoothly and efficiently, regardless of the driving conditions.

Whether you're cruising down the highway or pushing your engine to the limit, multiple venturi carburetors are designed to deliver exceptional performance and reliability.

Primary and Secondary Barrels

In a carburetor, primary and secondary barrels work together to deliver the best fuel-air mixture, adapting to your engine's changing needs. As you drive, the primary barrels handle lower load conditions, such as idling or cruising, providing a precise fuel delivery for peak performance.

However, when you need more power, the secondary barrels kick in, increasing fuel delivery to meet the higher engine load demands.

In two-barrel carburetors, you'll find one primary and one secondary barrel, which provides flexibility for different driving situations. On the other hand, four-barrel carburetors feature two primary and two secondary barrels, offering even more precise fuel delivery and adaptability to diverse driving scenarios.

The smooth shift between primary and secondary barrels guarantees an ideal fuel-air mixture, regardless of whether you're accelerating, decelerating, or cruising. This precise fuel delivery translates to enhanced engine performance, efficiency, and overall driving experience.

High-Performance Carburetors

When you're looking to extract maximum power from your engine, high-performance carburetors like four-barrel designs optimize fuel and air mixture for increased engine power and efficiency. These high-performance carburetors are designed to deliver more fuel to high-displacement engines, enhancing performance. They often pair well with dual-plane intake manifolds, which enhance airflow and fuel delivery.

Upgraded accelerator pumps in high-performance carburetors provide quick fuel delivery for rapid acceleration. Furthermore, these carburetors often feature larger venturi sizes and specialized tuning for racing and high-power applications. This specialized tuning allows for precise fuel and air mixture control, making high-performance carburetors ideal for racing applications and high-power engines.

Float-Type Carburetors Explained

Floating effortlessly on top of the fuel, the float-type carburetor's bopper regulates fuel levels within the float chamber, ensuring a consistent supply to the engine. This mechanism allows for a reliable fuel delivery system, making float-type carburetors a popular choice for small aircraft. The float chamber plays a vital role in maintaining the ideal air-fuel mixture for engine combustion. As the fuel level in the chamber decreases, the float mechanism adjusts the fuel flow to compensate, guaranteeing a consistent supply to the engine. This precise control over fuel levels is critical for efficient engine performance.

| Feature | Description | Importance |

|---|---|---|

| Float Mechanism | Regulates fuel flow based on fuel levels | Ensures consistent fuel supply |

| Float Chamber | Maintains ideal fuel levels | Enables efficient engine combustion |

| Fuel Delivery System | Provides reliable fuel supply | Critical for small aircraft operations |

Pressure-Type Carburetors Defined

You're likely familiar with the reliability of float-type carburetors, but pressure-type carburetors elevate fuel delivery to the next level by delivering fuel under pressure to the engine cylinders for combustion.

This design guarantees consistent fuel flow under varying engine loads and operating conditions, making it ideal for high-performance engines. Unlike fuel injection systems, pressure-type carburetors use a pressurized system to force fuel into the intake manifold, where it's sprayed directly into the airflow, creating a more efficient fuel-air mixture.

This results in a smoother, more efficient combustion process, reducing the likelihood of your engine to run rough. In a pressure-type carburetor, fuel is delivered directly to the combustion chamber, allowing for precise fuel delivery and peak engine performance.

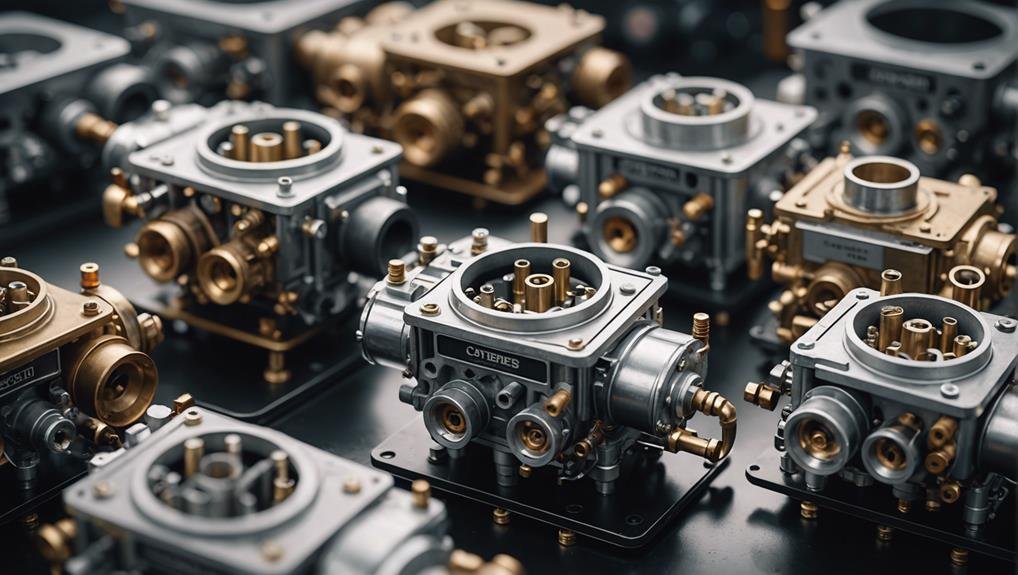

Materials Used in Carburetors

As you investigate the inner workings of a carburetor, it becomes evident that the selection of materials plays a crucial role in guaranteeing excellent fuel flow and engine performance. The carburetor bodies, for instance, are typically made from lightweight aluminum or alloy materials, which provide durability and performance.

Moving parts within the carburetor, such as throttle valves, are commonly crafted from steel or stainless steel for strength. Fuel jets and screws, on the other hand, are often made from brass due to its smooth machining properties and resistance to tarnishing.

The use of specific materials in carburetors helps ensure smooth fuel flow, precise metering, and resistance to corrosion. By using the right materials, you can optimize engine performance and prolong the lifespan of your carburetor.

Regular maintenance, including cleaning, adjusting, and inspecting, can also help extend the life of your carburetor. By understanding the materials used in carburetors, you can make informed decisions when selecting or repairing your carburetor, ultimately leading to better engine performance.

Selecting the Right Carburetor

When upgrading or replacing your carburetor, selecting the right one for your engine's specific needs is vital to achieving peak performance. You'll need to take into account the engine size and performance requirements to guarantee the carburetor can provide the correct air and fuel mixture.

Different types of carburetors, such as single-barrel, two-barrel, and four-barrel, cater to varying engine requirements. It's important to verify compatibility with the intake manifold for proper fit and performance. Manufacturers often publish specifications for carburetor compatibility with specific engines, so be sure to check those before making a purchase.

In addition, consider the throttle response and performance you're aiming to achieve. For vintage cars from the 1940s to the 1970s, aftermarket carburetors are a popular choice due to their availability and ease of installation.

Frequently Asked Questions

What Are the Three Different Types of Carburetors?

You're wondering what the three main types of carburetors are? Well, you'll find single barrel, double barrel, and quad barrel carburetors, each catering to specific engine needs, from basic to high-performance fuel-air mixing.

How Do I Figure Out What Carburetor I Need?

To figure out what carburetor you need, you'll determine your engine's size, number of cylinders, and intended use, then consider fuel system type, venturi size, and CFM rating to find the perfect match for your vehicle.

How Are Carburetors Classified?

You'll find that carburetors are classified based on the number of venturi tubes, with single, double, and quad configurations, in addition to their venturi design, fuel delivery mechanisms, and airflow direction, which suits specific engine requirements.

What Is a 4 BBL Carburetor?

You're wondering what a 4 BBL carburetor is? It's a four-barrel carb that provides more power and efficiency, featuring four venturi for a higher volume of fuel and air mixture, perfect for high-performance vehicles.

Conclusion

Now that you've examined the different types of carburetors, you're better equipped to choose the right one for your vehicle. Remember, selecting a carburetor depends on factors like engine size, horsepower, and driving conditions.

By understanding the differences between single venturi, multiple venturi, float-type, and pressure-type carburetors, you'll be able to optimize your engine's performance and fuel efficiency.

Take your newfound knowledge to the garage and prepare to rev up your ride!