As you investigate how the internal combustion engine works, you'll uncover an intricate process where air, fuel, and spark combine to produce power. The engine's four strokes – intake, compression, power, and exhaust – propel the conversion of chemical energy into mechanical force. Key components like the engine block, cylinder head, and camshaft work together to facilitate the combustion process, which sets off a series of controlled explosions that ultimately turn the crankshaft. To understand the intricacies of this process, you'll want to delve deeper into the mechanics of fuel ignition, valve timing, and combustion chamber design, where the secrets to efficient power generation await.

Key Takeaways

- The four-stroke cycle (intake, compression, power, and exhaust) is the fundamental process by which internal combustion engines generate power.

- Air and fuel are ignited by a spark plug, producing a controlled explosion that drives the piston, ultimately converting chemical energy into mechanical energy.

- The crankshaft converts the up-and-down motion of the pistons into rotational energy, which is then transmitted to the transmission and eventually the wheels.

- The valve train, consisting of intake and exhaust valves, regulates airflow in and out of the cylinders, ensuring efficient combustion and minimizing emissions.

- The combustion chamber, where fuel ignition occurs, is a critical component, and its design has a significant impact on engine performance, efficiency, and emissions.

The Four Strokes of Combustion

Typically, when you pop the hood of a car, you'll find an internal combustion engine relying on the four strokes of combustion to convert chemical energy into mechanical energy.

These strokes – intake, compression, power, and exhaust – work in harmony to generate power. During the intake stroke, the piston moves down the cylinder, drawing in a mixture of air and fuel to prepare for combustion.

Next, compression occurs, where the piston moves back up, compressing the air-fuel mixture to increase its potency for ignition. The power stroke is when the spark plug ignites the compressed mixture, generating force that drives the piston down to create power.

Lastly, during the exhaust stroke, the spent combustion gases are expelled from the cylinder as the piston moves back up, clearing the way for a new intake cycle. This continuous process allows the engine to convert chemical energy from fuel into mechanical energy, ultimately propelling your vehicle forward.

Engine Components Overview

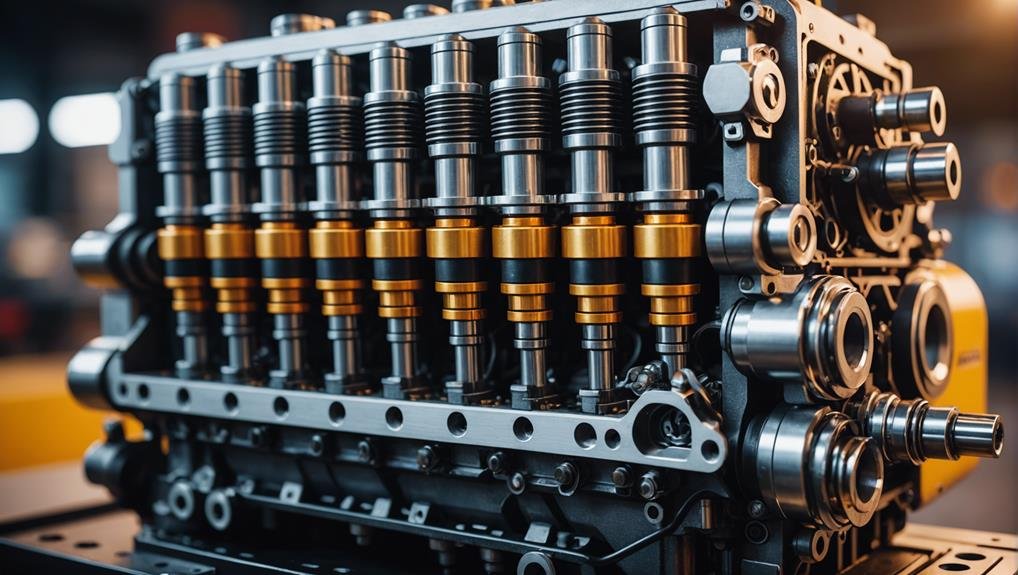

As you investigate the internal workings of an engine, you'll find that several critical components work in tandem to facilitate the four-stroke combustion process, converting chemical energy into mechanical energy.

The engine block, housing the pistons and crankshaft, forms the foundation of the engine.

The cylinder head, containing the camshaft, valves, and spark plugs, sits atop the block.

The combustion chamber, formed by the piston, cylinder head, and block, is where the magic happens.

The camshaft synchronizes with the crankshaft to control the opening and closing of intake and exhaust valves, essential for efficient engine operation.

The piston, connected to the crankshaft via a connecting rod, plays a significant role in converting thermal energy from combustion to mechanical energy for propulsion.

Understanding the interaction and precise coordination of these components is crucial for optimizing engine performance and ensuring smooth operation.

How Fuel Ignition Works

When you turn the key or press the ignition button, the engine's fuel ignition system springs into action, relying on a spark plug to create the high-voltage spark that ignites the air-fuel mixture in spark ignition engines.

This process is essential for the internal combustion engine (ICE) to function, as it enables the combustion of the air-fuel mixture, generating power to drive the engine.

In spark ignition engines, the spark plug creates an electric spark to ignite the mixture, whereas in compression ignition engines, like diesel, the high pressure of the compressed air-fuel mixture ignites without a spark.

The timing and precision of fuel ignition are crucial for efficient engine operation and performance. Successful fuel ignition leads to the rapid combustion of the air-fuel mixture, generating power to drive the engine.

As the combustion gases push the piston down, it rotates the crankshaft, ultimately turning the wheels of your vehicle.

The intake and exhaust valves, controlled by the valve timing, ensure a smooth flow of fuel and air into the engine, enabling the fuel ignition process to occur efficiently.

Engine Power Conversion Process

Now that the air-fuel mixture is ignited, you're ready to see how the engine converts the resulting energy into power that drives your vehicle.

This conversion process involves controlled explosions of the air-fuel mixture inside the engine's cylinders, which are strategically designed to optimize efficiency. As the mixture ignites, it pushes the piston down, connected to a crankshaft that transforms the linear motion into rotational motion.

This rotational motion is what ultimately generates torque, the force that propels your vehicle forward. The engine's combustion cycle, consisting of four strokes – intake, compression, power, and exhaust – is essential for converting thermal energy to mechanical energy efficiently.

As the piston moves up and down, it creates a continuous motion that drives the crankshaft, ultimately transmitting the torque to the wheels. This intricate process is what enables the internal combustion engine to convert the heat energy from burning fuel into mechanical work, making it possible for your vehicle to move.

Types of Internal Combustion Engines

You'll encounter a variety of internal combustion engine types, each designed to optimize performance in specific applications. Gasoline engines, also known as spark-ignition engines, are widely used in passenger vehicles, utilizing intake valves to draw in air and fuel, and exhaust valves to release exhaust gases.

Diesel engines, on the other hand, are compression-ignition engines, relying on the heat generated during the compression stroke to ignite the fuel. Direct injection technology is often used in these engines to improve efficiency.

Rotary engines, like the Wankel engine, are less common, but offer a unique design that replaces traditional pistons and cylinders with a rotor. The power stroke, where the fuel ignites, is a critical phase in the engine's operation, preceded by the compression stroke, where the air-fuel mixture is compressed.

You'll also find specialized engines, such as two-stroke, Clerk cycle, and Day cycle engines, each with their own strengths and weaknesses. Understanding the different types of internal combustion engines is essential for selecting the right engine for a particular application.

Engine Structure and Design

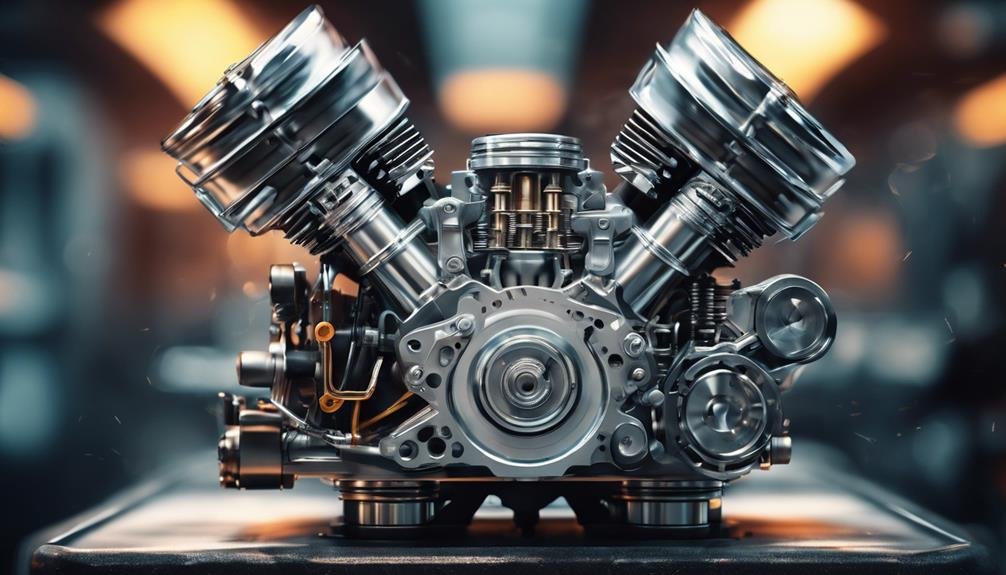

In every internal combustion engine, a delicate balance of fixed and moving components works in harmony to convert chemical energy into mechanical power. As you investigate the internal workings of an engine, you'll find that the cylinder block, crankshaft, and piston form the core of the internal combustion engine.

Here are three key components that work together to make the engine run:

- Cylinder block: Houses the piston, connecting rod, and crankshaft, crucial for converting thermal energy from combustion into mechanical work.

- Camshaft and valves: Work in synchrony with the crankshaft to maintain proper valve timing and piston movement.

- Combustion chamber: Formed between the piston, cylinder head, and block, where the air-fuel mixture ignites and propels the engine.

In this intricate dance, the camshaft, valves, spark plugs, and injectors in the cylinder head work in harmony with the piston and crankshaft to guarantee the engine operates smoothly. The precise coordination of these components enables the internal combustion engine to convert chemical energy into mechanical power, making it possible for your car to move.

Combustion Chamber Function

As the piston reaches the top of its stroke, the air-fuel mixture is squeezed into the combustion chamber, where it's ignited, producing the power that drives your car forward.

This is where the magic happens in internal combustion engines. The combustion chamber, located within the cylinder head and block, is a critical component that influences factors like fuel efficiency, power output, and emissions. Its design plays a vital role in controlling the timing and intensity of combustion events within the engine.

A well-designed combustion chamber guarantees efficient and complete fuel burning, which is necessary for excellent engine performance. As you can imagine, the shape and size of the combustion chamber are crucial for achieving this. Proper combustion chamber design enables engines to produce the necessary power output while minimizing emissions.

Essentially, the combustion chamber is the heart of the engine, where the air-fuel mixture is ignited, producing the energy that propels your vehicle forward.

Crankshaft and Camshaft Operation

Rotating in tandem, the crankshaft and camshaft orchestrate the intricate dance of engine operation. The crankshaft converts the pistons' linear motion into rotational energy, while the camshaft synchronizes valve opening and closing.

As you explore further, you'll find that the crankshaft is connected to the pistons via connecting rods, transferring the engine's power to the transmission. The camshaft controls the opening and closing of the intake and exhaust valves in coordination with the crankshaft. This harmonious relationship allows the engine to breathe, generating power.

Here are three key takeaways about the crankshaft and camshaft:

- Crankshaft converts linear motion to rotational energy, driving the vehicle forward.

- Camshaft regulates valve opening and closing, ensuring proper engine breathing.

- Both components work together to generate engine power and maintain smooth operation.

Valve Train and Piston Movement

You've seen how the crankshaft and camshaft work together to generate power; now, let's examine how the valve train and piston movement synchronize to regulate airflow and fuel intake.

The valve train, which controls the opening and closing of intake and exhaust valves, is precisely timed to work in harmony with piston movement. As the piston moves up and down, the valve train ensures that the intake valves open to let in air and fuel, and the exhaust valves open to release exhaust gases. This synchronization is crucial for peak engine performance and power delivery.

The piston's reciprocating motion is converted into rotational motion by the crankshaft, which relies on the precise timing of the valve train to function efficiently. Proper coordination between the valve train and piston movement ensures smooth engine operation, as it allows for the efficient intake of air and fuel and the expulsion of exhaust gases.

Engine Performance and Efficiency

Over the past three decades, internal combustion engines have undergone significant transformations, resulting in remarkable improvements in performance and efficiency, with notable gains in horsepower, acceleration, and fuel economy. As you investigate the inner workings of an internal combustion engine, it's important to grasp the factors that contribute to its performance and efficiency.

Here are three key aspects that impact an internal combustion engine's performance and efficiency:

- Air and Fuel Mixture: The precise mixture of air and fuel is vital for excellent combustion, which directly affects the engine's performance and efficiency.

- Efficient Combustion: The effective combustion of fuel and air mixtures ensures that the engine produces the maximum amount of energy while minimizing emissions.

- Energy-Efficient Designs: Modern internal combustion engines are crafted to be energy-efficient, reducing emissions and minimizing waste energy.

As manufacturers continue to focus on making internal combustion engines more energy-efficient while minimizing emissions, you can expect even more significant improvements in performance and efficiency. By understanding these key aspects, you'll gain a deeper appreciation for the complex processes that occur within an internal combustion engine.

Frequently Asked Questions

What Is Internal Combustion Engine Full Explanation?

You're probably wondering what an internal combustion engine is – it's a device that converts fuel energy into mechanical work through a four-stroke cycle, driving a piston to produce power, and it's what powers most vehicles.

How Does an Engine Work Step by Step?

You start by learning the four-stroke process: intake, where air-fuel mixture enters the cylinder, then compression, power, and exhaust, where burned gases exit, working together to generate power in a continuous cycle.

What Three Things Does an Internal Combustion Engine Work?

You're wondering what an internal combustion engine does, right? It works to convert thermal energy, generate mechanical work, and produce rotational motion – these three key functions make it a powerhouse for diverse applications!

How Does the First Internal Combustion Engine Work?

You're curious about the initial internal combustion engine, patented by Robert Street in 1794. It used liquid fuel for combustion, which was a groundbreaking innovation at the time, marking the beginning of a new age in engine technology.

Conclusion

As you now understand the intricacies of internal combustion engines, you've gained a deeper appreciation for the complex dance of components working together to convert chemical energy into mechanical power.

From fuel ignition to crankshaft rotation, each step plays a critical role in the engine's operation.

With this knowledge, you'll better comprehend the inner workings of your vehicle, allowing you to make more informed decisions as a driver and potentially even perform simple maintenance tasks on your own.