Your engine relies on an essential component that houses the cylinders, pistons, and crankshaft, and is typically constructed from aluminum alloy or cast iron for strength, heat conduction, and cooling efficiency. This vital part, known as the engine block, regulates temperature, facilitates piston movement, and enables crankshaft rotation. Water cooling jackets, gaskets, and liners work together to optimize engine performance. As you investigate the intricacies of your engine, you'll uncover the significance of coolant and oil passages, crankcase and bearing functionality, and the importance of regular maintenance to prevent damage and ensure smooth operation – and that's just the beginning.

Key Takeaways

- The engine block is the main structure housing cylinders, pistons, and crankshaft, typically made from aluminum alloy or cast iron for strength and heat conduction.

- It contains water cooling jackets for regulating temperature and is the foundation for piston movement and crankshaft rotation, allowing for efficient heat transfer.

- The engine block is composed of various components, including cylinders, coolant passages, oil galleries, and gaskets, which require proper maintenance for smooth engine operation.

- The design and construction of the engine block have evolved over time, from separate components to integrated monobloc structures, improving engine performance and durability.

- Proper maintenance, inspections, and material selection are crucial to prevent engine block damage and ensure efficient engine operation.

What Is an Engine Block?

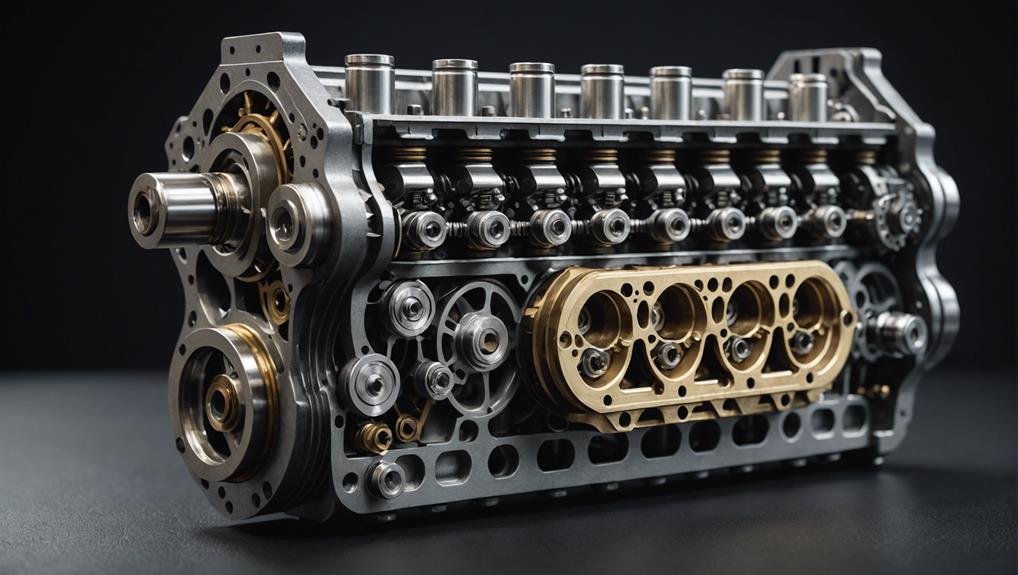

At the heart of your car's engine lies the engine block, the main structure that houses critical components like cylinders, pistons, and crankshaft. This fundamental component is typically made from either aluminum alloy or cast iron, chosen for their strength and heat conduction properties.

The engine block contains water cooling jackets, which play a crucial role in regulating the engine's temperature. As the foundation for piston movement and crankshaft rotation, the engine block plays a significant role in the combustion process.

Leaks from the engine block can occur due to issues like porous construction or faulty gaskets, affecting engine performance. It's important to maintain your engine block to prevent such issues. The engine block's design allows for efficient heat transfer, ensuring the engine runs smoothly.

Engine Block Construction Explained

When you take a closer look at an engine block's construction, you'll find a sophisticated design that balances strength, heat transfer, and component integration. Engine blocks are typically made from aluminum alloy or cast iron, providing strength and efficient heat transfer. The construction includes water jackets that are cooled by the car's radiator to maintain ideal operating temperatures. This design enables efficient heat transfer, which is vital for the combustion process.

| Component | Material | Function |

|---|---|---|

| Engine Block | Aluminum alloy or cast iron | Provides strength and heat transfer |

| Water Jacket | Aluminum alloy or cast iron | Cools the engine block |

| Cylinders | Aluminum alloy or cast iron | Houses pistons for combustion |

| Gaskets | Rubber or synthetic materials | Seals engine block components |

The engine block plays an important role in the combustion process by supporting cylinders, pistons, and the crankshaft. However, common problems can arise, such as external and internal coolant leaks, porous blocks, and issues with gaskets or seals. These issues can be costly and time-consuming to repair. Understanding the construction of an engine block is vital for maintaining and repairing your vehicle's engine.

Cylinder Block and Liners

You'll explore the cylinder block, the main structure of an engine, housing the cylinders, coolant passages, and oil galleries, playing a critical role in engine performance and durability.

The cylinder block is basically the engine block, which has evolved from separate components to modern monobloc designs for efficiency and cost-effectiveness.

Within the cylinder block, you'll find cylinder liners, also known as sleeves, which are inserted to provide a smooth surface for the piston movement.

The design of the cylinder block and liners is crucial to engine performance, durability, and maintenance. Proper maintenance of these components is crucial for efficient engine operation and longevity.

The cylinder block's design integration has significantly improved over time, allowing for better engine performance and durability. As you delve deeper into the cylinder block, you'll appreciate the complexity and importance of this critical engine component.

Coolant and Oil Passages

As you investigate the engine block further, the important role of coolant passages and oil galleries comes into focus, emphasizing the significance of temperature control and lubrication in maintaining peak engine performance.

These passages and galleries are vital components, guaranteeing that your engine operates within a safe temperature range and receives the necessary lubrication for smooth function. Coolant passages dissipate heat generated during operation, while oil galleries facilitate the flow of lubricant to moving parts.

Proper coolant circulation and oil flow are essential for maintaining engine performance, longevity, and overall health.

As you explore further, it becomes clear that these systems are crucial for temperature control and lubrication, allowing your engine to run efficiently and effectively.

Regular maintenance of coolant and oil systems is necessary to ensure the health and efficiency of your engine, preventing damage and promoting excellent performance.

Crankcase and Bearing Function

The crankcase, nestled within the engine block, plays a vital role in housing the crankshaft, connecting rods, and main bearings, providing a protective environment for these critical components to function smoothly. As you delve into the inner workings of your engine, you'll find that the crankcase is crucial for supporting and protecting the moving parts that convert linear motion into rotational motion.

| Component | Function | Importance |

|---|---|---|

| Crankshaft | Converts linear motion into rotational motion | Vital for engine operation |

| Bearings | Reduces friction between moving parts | Prevents wear and damage |

| Crankcase | Houses and protects critical components | Provides a protective environment |

Proper lubrication is crucial for the crankcase and bearings to function smoothly and efficiently. Without it, friction would increase, causing wear and damage to the moving parts. By understanding the crankcase and bearing function, you'll appreciate the intricate design of your engine and the importance of regular maintenance to keep it running smoothly.

Engine Block Materials Used

Your engine block's material composition plays an essential role in determining its general performance, longevity, and ability to withstand the stresses of combustion and operation.

In terms of engine block materials, you'll commonly find two options: aluminium alloy and cast iron. Aluminium alloy blocks offer a lightweight advantage, efficient heat transfer, and sufficient strength, making them a popular choice for many modern engines.

On the other hand, cast iron blocks are renowned for their exceptional durability, resistance to wear, and heat transmission capabilities. The choice between these materials largely depends on factors such as cost, performance requirements, and weight considerations.

As the engine block houses important components like cylinders, coolant passages, and oil galleries, its material composition significantly impacts engine performance. By selecting the right material, engineers can achieve the perfect balance between strength, heat transfer, and durability, ultimately ensuring a smoother, more efficient engine operation.

Common Engine Block Problems

Engine block problems can creep up on you, and it's important to recognize the warning signs to prevent minor issues from becoming major headaches.

One common issue is external engine coolant leaks, which can result from a holed hose or a faulty water pump. Internal engine coolant leaks, on the other hand, may stem from a defective gasket within the engine block.

You should also be aware of porous engine blocks, caused by manufacturing contaminants, which can lead to minor leaks. Broken seals on engine blocks are typically considered wear and tear and may not be covered by warranty.

Leaks from porous engine blocks can be a common problem that requires repair. A faulty gasket can also lead to internal engine coolant leaks, which can be difficult to detect. It's important to address these issues promptly to prevent further damage.

Engine Block Design and Evolution

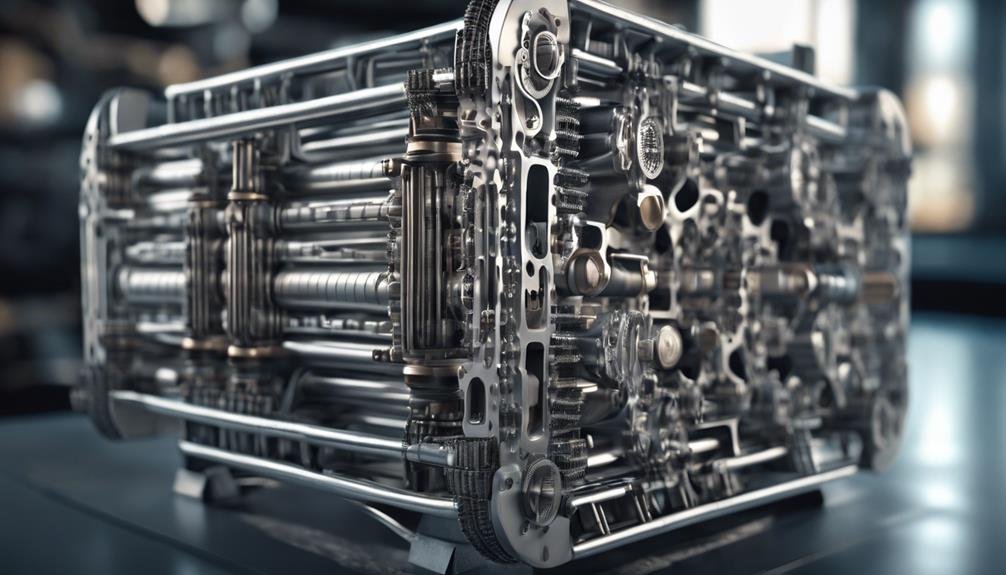

As you investigate the heart of an engine, you'll find that the block's design has undergone significant transformations over the years. The evolution of engine blocks has been shaped by advancements in materials, foundry technologies, and machining technologies. Initially, engine blocks consisted of separate components, but modern designs have shifted to integrated monobloc structures for improved strength and efficiency.

| Design Evolution | Key Features |

|---|---|

| Early Engine Blocks | Separate components, heavy, and limited power output |

| Integrated Monobloc Structures | Lightweight, improved strength, and increased power output |

| Modern Engine Blocks | Aluminum alloy and cast iron materials, advanced machining technologies |

| Ford Flathead V8 | Pioneered V8 engine design, influenced modern engine block development |

The use of aluminum alloy and cast iron materials has enabled engine blocks to withstand high temperatures and pressures. The Ford flathead V8 engine, in particular, played a significant role in the evolution of engine block design, especially for V8 engines. As you immerse yourself deeper into the world of engine blocks, you'll uncover how these design transformations have optimized engine performance and efficiency.

Engine Block Maintenance Tips

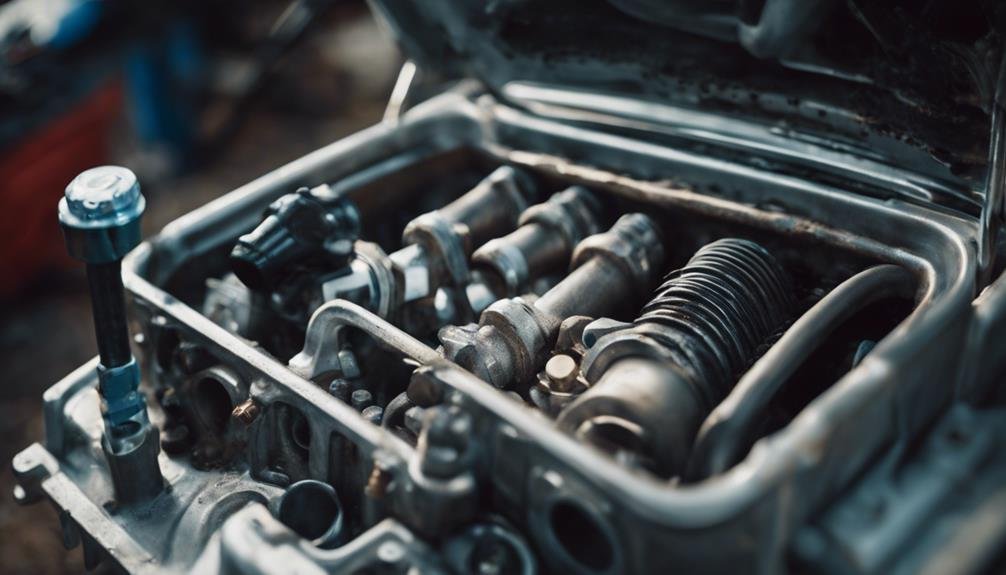

By staying on top of routine maintenance, you can greatly increase the lifespan of your engine block and prevent costly repairs down the road. Regular inspections are vital to identifying potential issues before they cause damage. Check your engine block for leaks, which can lead to coolant or oil loss, causing significant harm to your engine.

Moreover, monitor cylinder wear to catch any issues early on, as excessive wear can lead to engine failure. Inspect your engine block for casting imperfections that may lead to leaks or other problems. Don't forget to replace freeze out plugs if they show signs of wear or damage, as they can cause coolant leaks if not properly maintained.

Using proper coolant and oil is also important to maintaining engine block health and performance. By following these maintenance tips, you can minimize the risk of potential damage and ensure your engine block runs smoothly for years to come.

Frequently Asked Questions

How Does the Engine Block Work?

You're wondering how the engine block works? Well, you're about to find out! The engine block supports the crankshaft, camshaft, and pistons, allowing them to move smoothly, while its coolant passages and oil galleries facilitate heat dispersion and lubrication.

What Does the Block Do in a Car Engine?

You're wondering what the block does in a car engine. In short, it supports the cylinders, houses the crankshaft, and facilitates heat transfer, allowing for smooth combustion, power generation, and efficient cooling.

What Are the Parts of the Engine Block?

You're wondering what parts make up the engine block. Well, it's comprised of cylinder bores housing pistons, water cooling jackets, oil passages for lubrication, and a crankcase supporting the crankshaft and camshaft.

What Are the Three Types of Engine Blocks?

You're wondering about the three types of engine blocks, right? Well, they are inline, V-shaped, and flat engine blocks, each with its unique cylinder arrangement, affecting engine performance, space, and vehicle design.

How to Tell if an Engine Block Is Bad?

You'll know your engine block is bad if you notice coolant leaks, overheating, or unusual noises; inspect for signs of damage, corrosion, or cracks, and check for faulty gaskets or freeze plugs causing issues.

Conclusion

Now that you've explored the world of engine blocks, you've gained a deeper understanding of this vital component.

From its construction and materials to its functions and common problems, you're better equipped to appreciate the complexity of your vehicle's engine.

Remember, regular maintenance is key to extending the life of your engine block, so be sure to stay on top of oil changes, coolant checks, and other important tasks to keep your engine purring smoothly.